- Company

- Services

- Fields of Expertise

- Publications

- References

- Contact

- EN DE

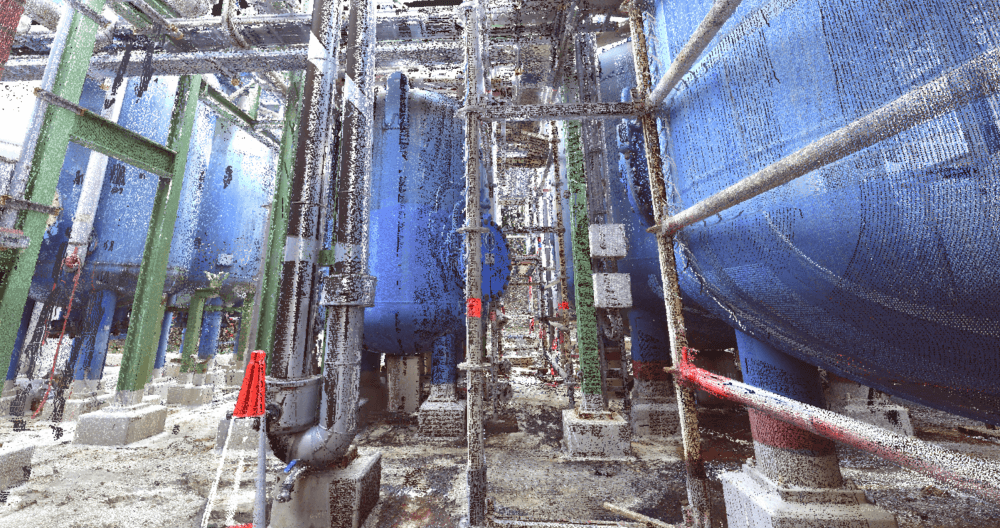

With the help of 3D-Laserscanning technologies, we can digitize existing facilities including the surrounding plant site and relevant infrastructures. Here are some of the many benefits digitizing your facility can provide:

For example, one of the solutions we have used in the past is the Leica RTC360 from Leica Geosystems AG. It is a fast and precise measuring tool. It is important to note that the RTC360 3D laser scanner has a minimum scanning range of 0.5 meters and a maximum scanning range up to 130 meters. The dimensions of the scanner are 120 mm x 240 mm x 230 mm. Apart from the hardware we are also accustomed to the official software Leica Cyclone REGISTER 360, the instrument includes.

For example, one of the solutions we have used in the past is the Leica RTC360 from Leica Geosystems AG. It is a fast and precise measuring tool. It is important to note that the RTC360 3D laser scanner has a minimum scanning range of 0.5 meters and a maximum scanning range up to 130 meters. The dimensions of the scanner are 120 mm x 240 mm x 230 mm. Apart from the hardware we are also accustomed to the official software Leica Cyclone REGISTER 360, the instrument includes.

In order to digitize the plant, a measuring instrument called a 3D scanner is set up at various positions and then is used to record data points as well as take high-resolution images. This measuring instrument scans surfaces using laser beams in a grid pattern. The geometry of the environment is then stored as a collection of individual 3D points. These data points and images are then used with specialized software in order to create a 3D model of the existing facility. The achievable resolution is in the range of a few millimetres of accuracy.

Due to their high resolution, the images can be used for 360° tours. This allows you to present your plant ideally and give outsiders a virtual tour without them being present on site. You can find an example of such an interactive model here:

STEP Consulting GmbH is at your side as a strong partner. We offer assistance in laser scanning and in the integration of process engineering and civil engineering components into your existing infrastructure. Take a step further into the digital future of plant design with us. We look forward to your inquiries.

The digital 3D model of the plant allows us to fly through the plant on a digital scale: